S55 Sweet Spot

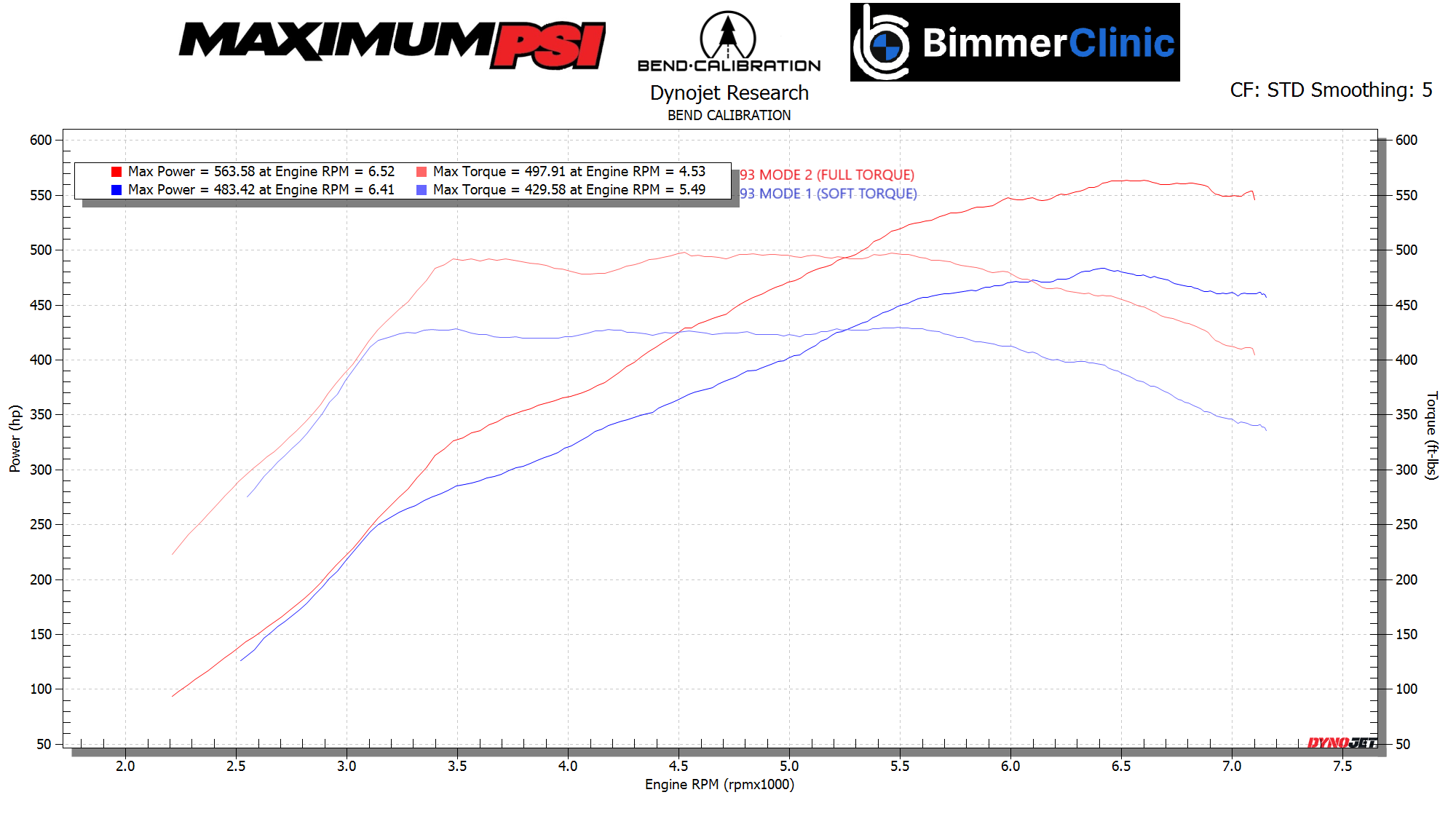

See above for the Mode2 and Mode1 (Maps as referred to in MHD) with a car running a mix of 71% ethanol.

See above for Mode 1 and Mode 2 (referred to as “Maps” in MHD) on a car running 93 octane. Mode 1 is the conservative calibration, while Mode 2 pushes performance closer to the octane limit. Both modes seamlessly blend based on the ethanol content in your fuel, so whether you fill up with E85, 93, or any mix in between, the calibration automatically adjusts.

That means no hassle with flashing tunes at the pump, just fill up and drive. This true flex-fuel integration is one of the key features that set our calibrations apart. If you’re comparing options for calibration work, make sure you’re evaluating a genuine flex-fuel setup like this for an apples-to-apples comparison.

So what is the Sweet Spot? After countless S55 powered cars ranging from stock turbo setups all the way up to 1200+whp single turbo drag cars we have found what we believe to be the sweet spot and here it is:

-Mosselman MSL65-80 turbos

-Wagner Top Mount Intercooler and heat exhanger

-EU5 Injectors

-Dorch Lift Kit

-PFS S55 F8X Drop in Brushless LPFP

-Bend Calibration Ultimate Flex Fuel Kit

-Bend Calibration Ecutek Custom Flex Tune

It's a setup that you literally just fill up with any blend of ethanol or pump fuel and go. The turbos, fuel system, and air handling are all matched to the stock engine nicely.

-Taking methanol injection and port injection hardware and electronics out of the equation significantly simplifies the setup and reduces the chances of costly delivery systems failure.

-These turbos spool almost as quickly as stock, deliver power much more smoothly, and about 1000rpm quicker than the larger, more common turbocharger upgrades (PS2+). Another benefit of the Mosselman turbos is their lower price and higher reliability due to being brand new cores and not rebuilds.

-Stock airboxes with drop in BMC filters. Aftermarket intake systems typically make less power and often introduce surge and exasperate bank-to-bank airflow imbalance issues so common with these cars.

-PFS S55 F8X Drop in Brushless LPFP upgrade pairs with the Dorch Lift kit to match the delivery capability of the EU5 injectors. We have mapped out where the stock LPFP, HPFP, and injectors reach their capacity and there is not "one answer" to a complex question. We often hear "this" or "that" is the limit but that is not correct since each of these components limit at different RPM, load, and ethanol values. Our combination requires our bespoke control strategy to work correctly. Further, a dyno pull shows different limitations than a multi gear pull and we've got a handle on how to identify all of these variables.

-Our specific injection and fuel system control strategies monitor the fuel system component workload in ways we have not seen any other calibrators datalog, so without giving away too much, we believe we have the upper hand in finding the right window for fuel delivery.

-There are limitations with rod strength is well documented and we'd like to note that some of these cars will live with 650+ tq for a long time but we've seen rods spit out as low as 600tq so your mileage may vary. This is well known by other high volume facilities but not often talked about. Not every mechanical part has an identical failure point, which is why some room should be left on the table for a reliable setup.

-There are some valvetrain concerns with the stock cylinder head which is also well documented. However, we have optimized camshaft timing to help with some of that issue and are able to identify via datalogs when running into this. We've also found some variability in this from car to car which is to be expected when pushing to the limit.

We have recommendations for other Single/Built Motor setups that can help guide your build to something into your own sweet spot so feel free to reach out for a consultation. The client in this situation followed all of our build recommendations and was rewarded with a balanced, powerful, and efficient setup.

The original sweet spot above from 2022; in 2024 our sweet spot clients started running into issues with the PR Stage3 Brushless LPFP hence the newest recommendation of the PFS LPFP.

An expansion on fuel system limitations for the S55:

To try to put it simply, there are 3 separate limitations which all impact this engine at different RPM/load's, so there is not a simple one word answer to a question like this.

Injection window; the EU5's solve this by flowing more fuel in the same amount of time than the stock injectors, this relieves the short time between firing events with larger turbos that flow more air at high RPM (this is different with stock turbos)

HPFP where the injectors flow more fuel, the HPFP struggle to flow enough to maintain high rail pressure required to inject fuel over a short duration in the midrange

LPFP; when there is high flow demand @ high pressure from the HPFP, the LPFP is unable to provide sustained rail pressure to the HPFP for longer pulls (fuel consumption over time)

All three of the above impact a 600+whp S55 running ethanol fuel. Further variation comes with ethanol quantity etc. The solution we suggest covers the stock motor, bolt on turbos, full ethanol in the tank, and most other environmental variables. If you choose one or two of the three suggested parts, you will make the lowest common denominator of the combination of your parts.

Sweet Spot + Built motor

Below is a graph for the same setup, but with the addition of a built motor so we can push a bit harder without worrying about rod failure.